My very own first computer was an Atari 400 bought second hand by my Dad. My friend Simon was moving back home to Ireland so wouldn't be able use an NTSC machine. It came with a 410 tape drive, some cassettes (most of which I could never get to load), and some carts. Because the 400 hooked up to a TV, Atari engineers had to design a Faraday cage for the main board to pass FCC electromagnetic interference (EMI) requirements. This resulted in the machine needing a door to fit over the cartridge slot.

I recently bought a 400 off of eBay and unfortunately the shipper did not do a good job packing. The power supply rumbled around and beat up the case. I got half off - I figure I can fix it. The machine was missing one of the hinge brackets and the cover got loose and the other hinge bracket came up. I was able to recover the bracket, its screw, and the torsion spring. I ended up taking the whole machine apart so I could fix the case and clean it up. The money I got back from the damage claim was enough to buy a 48k RAM upgrade. So hey, I will come of the deal OK.

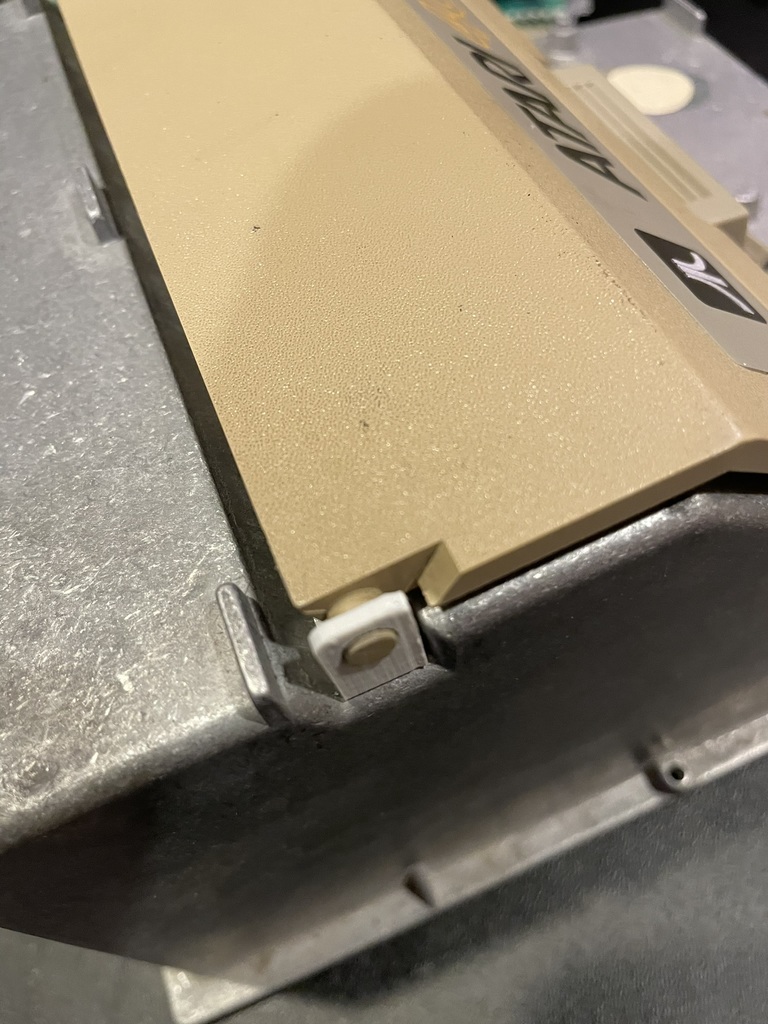

To replace the missing hinge bracket, I drew one up on Fusion 360 and printed it out. It fits quite nicely. The design is on Thingiverse.

|

| Replacement hinge bracket from the Atari 400 cart door. |